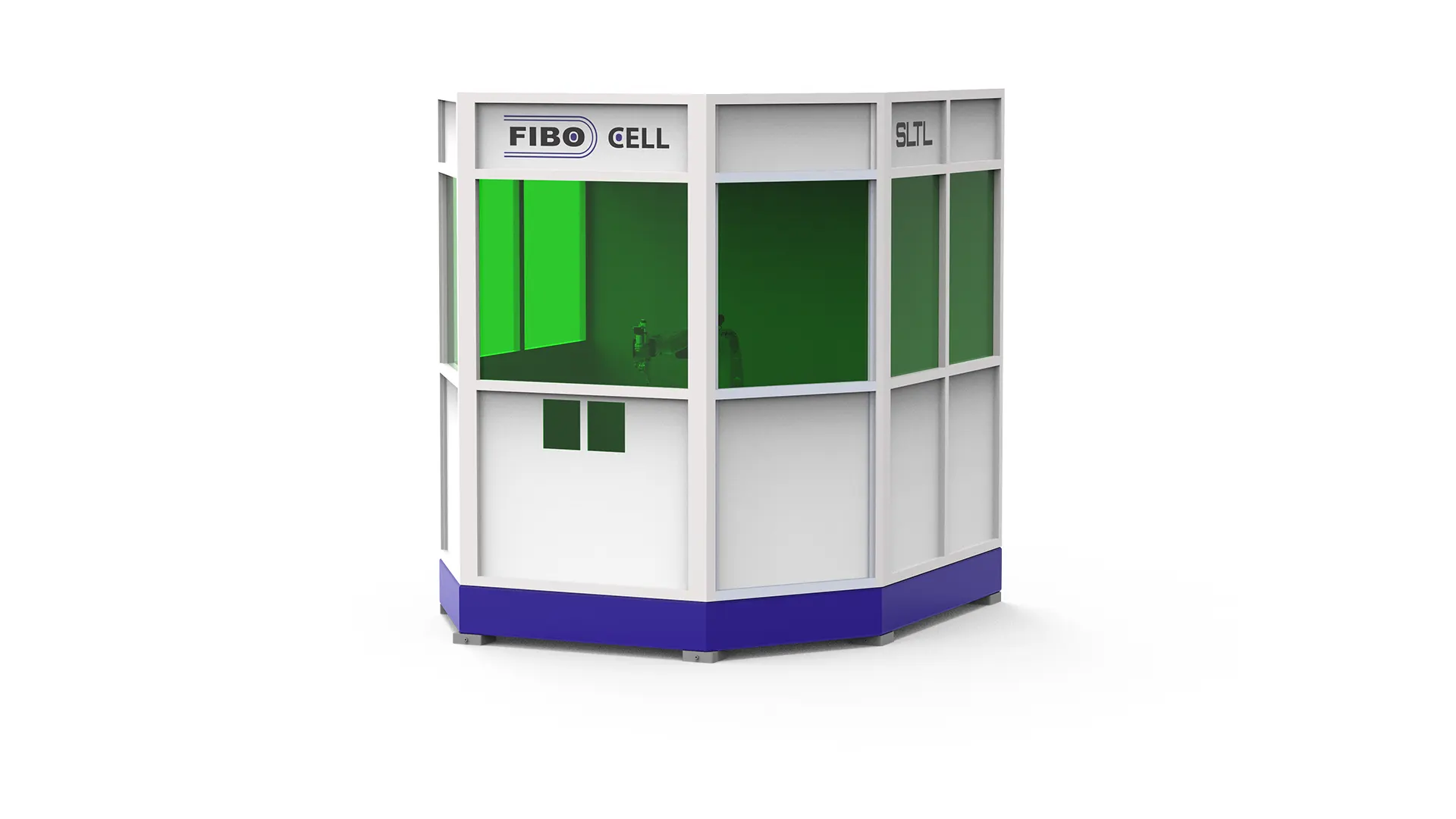

SLTL Fibo Cell Robotic Solution

The industry is moving fast, to meet it’s growing demand and to keep pace with its growth, it is important that we equip our factories with most advanced tools. SLTL Group introduces Fibo Cell. It is an advanced robotic automation system capable of carrying various operations. The robotic automation system when integrated with different modules it could perform tasks like hardening, cladding, welding, remote welding and cutting. With Fibo Cell’s high precise operations and efficient working, the productivity of the factory increases. It can be customized according to the need of business. With Fibo Cell is equipped with remote welding which allows you to control welding operations from distances. Henceforth, making it anytime-anywhere accessible machine.

Features and Benefits

- this is a list item

- this is a list item

- this is a list item