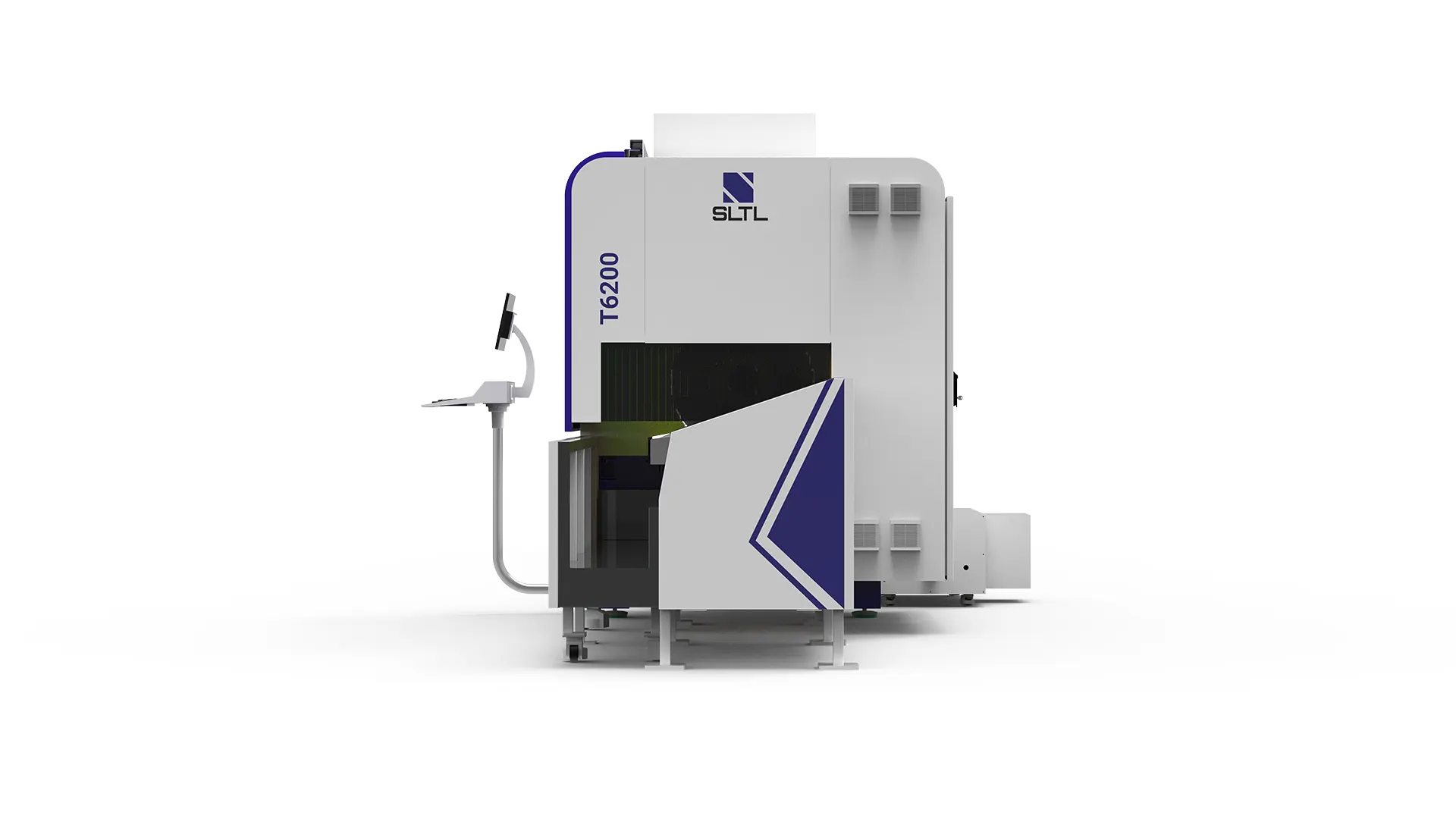

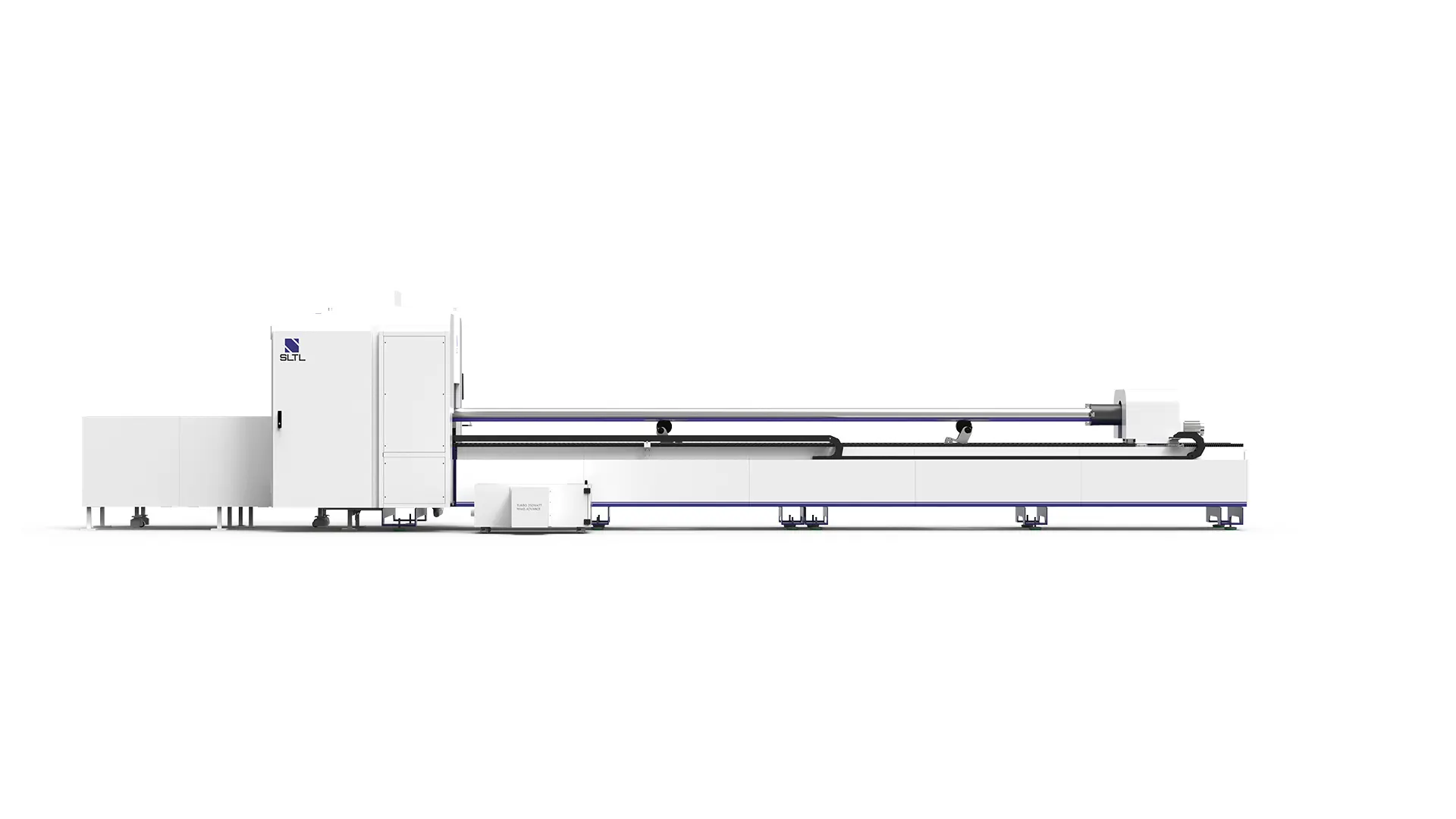

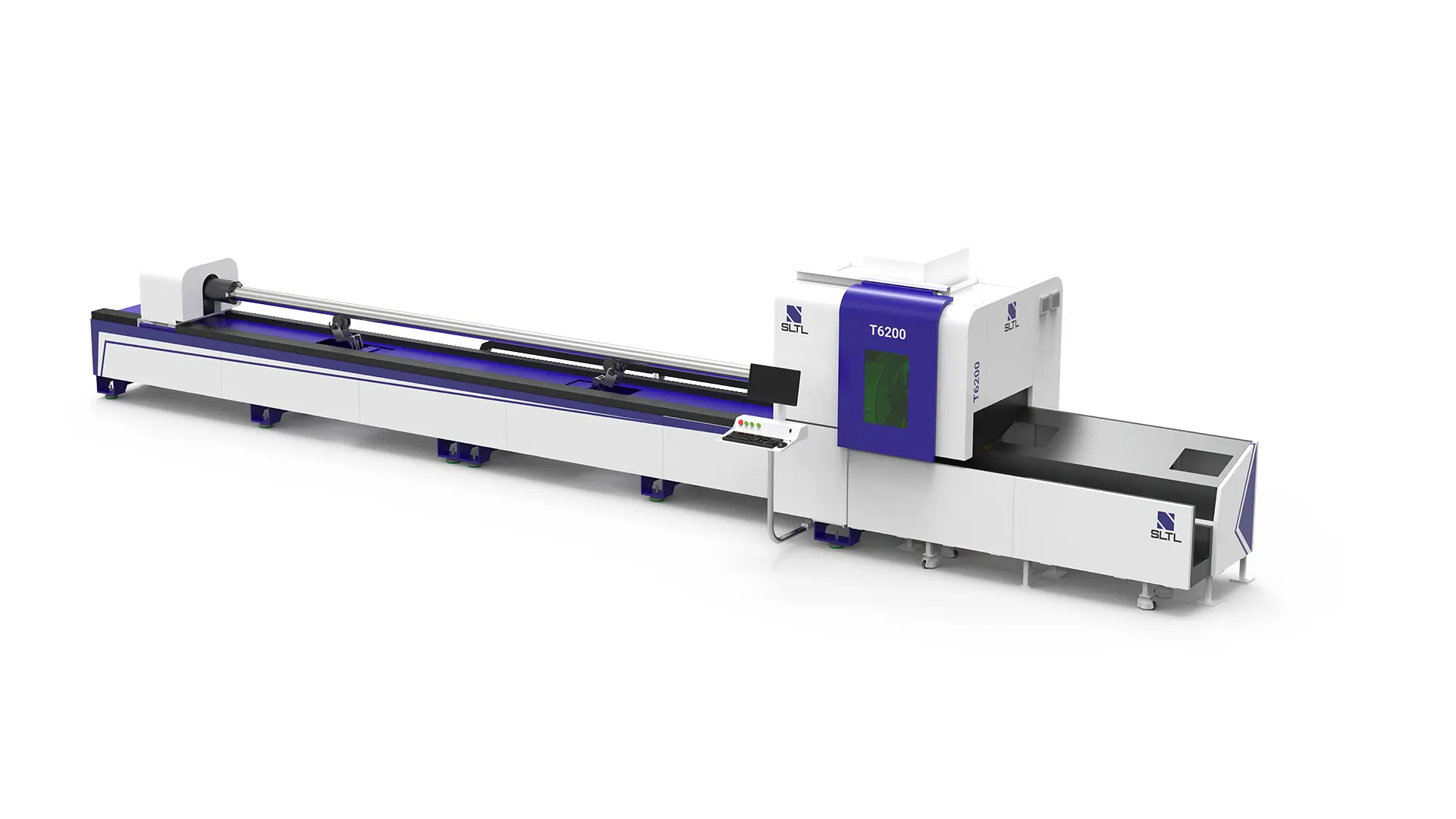

SLTL Laser Tube Cutting Series

Introducing a new way to process Laser Cutting on tubes with SLTL’s Tube Cutting Series; T6150 / T6200 / T6300. SLTL Group is well-known for revolutionizing the industry with ground-breaking innovations, and this Laser Tube Cutting series is turning out to be the Laser System that provides exceptional cutting quality and better productivity. This smart solution is a one-of-a-kind combination of the Group’s proprietary Laser Technology and a robust mechanical structure built by the company’s in-house R&D team. These dedicated Laser Tube Cutting Systems are built to provide extreme precision, productivity, and quality.

| Specification | Unit | T6150 | T6200 | T6300 | T8350 | |

|---|---|---|---|---|---|---|

| Maximum Pipe Cutting Length | mm | 6100 | 6100 | 6100 | 8050 | |

| Cutting Diameter | Round | Ø25 – Ø180 | Ø20 – Ø200 | Ø20 – Ø300 | Ø20 – Ø360 | |

| Rectangle / Square | mm | 120 x 120 | 150 x 150 | 200 x 200 | 150 x 300 / 250 x 250 | |

| X- Axis Travel | mm | 450 | 450 | 450 | 650 | |

| Y- Axis Travel | mm | 6050 | 6500 | 6500 | 9500 | |

| Z- Axis Travel | mm | 180 | 200 | 200 | 350 | |

| Maximum Job Weight | kgs | 140 | 160 | 225 | 670 | |

| Master Chuck Dia. Size (B1-Axis) | mm | 180 | 200 | 300 | 350 | |

| Master Chuck (B1-Axis) | Operation Manual / Auto | Operation Manual / Auto | Operation Manual / Auto | Operation Manual / Auto | ||

| Slave Chuck (B2-Axis) | Operation Manual / Auto | Operation Manual / Auto | Operation Manual / Auto | Operation Manual / Auto | ||

| X, Y Axis Positioning Accuracy | mm/meter | ±0.05 | ±0.05 | ±0.05 | ±0.05 | |

| X, Y Axis Repeatability Accuracy | mm/meter | ±0.03 | ±0.03 | ±0.03 | ±0.03 | |

| Acceleration | m/s² | 10 | 10 | 10 | 10 | |

| X Axis Maximum Running Speed | m/min | 45 | 45 | 70 | 70 | |

| Y Axis Maximum Running Speed | m/min | 70 | 70 | 70 | 70 | |

| Maximum Turning Speed (W-Axis) | rpm | 60 | 80 | 50 | 50 | |

| Laser Power | kW | 1, 2, 3, 4 | 1, 2, 3, 4 | 1, 2, 3, 4 | 1, 2, 3, 4 | |

| Controller | Tube Pro / etron | Tube Pro / etron | Tube Pro / etron | Tube Pro / etron | ||

Designed For Precision

The drive system in SLTL’s Laser Tube Cutting Machines prevents backlash and offers great stability to the processing. The system is capable of delivering excellent edge quality, efficient cutting and cost-effective processing. T6200 enables a refined laser tube cutting method that focuses on precision and the finest finish in every cut, at the same time; ensuring the same output in every cut.

Advanced Software

T6200 allows advanced nesting programs to be created and run on the system. The software provides flexibility for users to add, change or delete programs on the go. With Superfast pipe cutters integrated with smart software; users have the most comprehensive solution available on the market for automating production changeover between different materials and thicknesses.

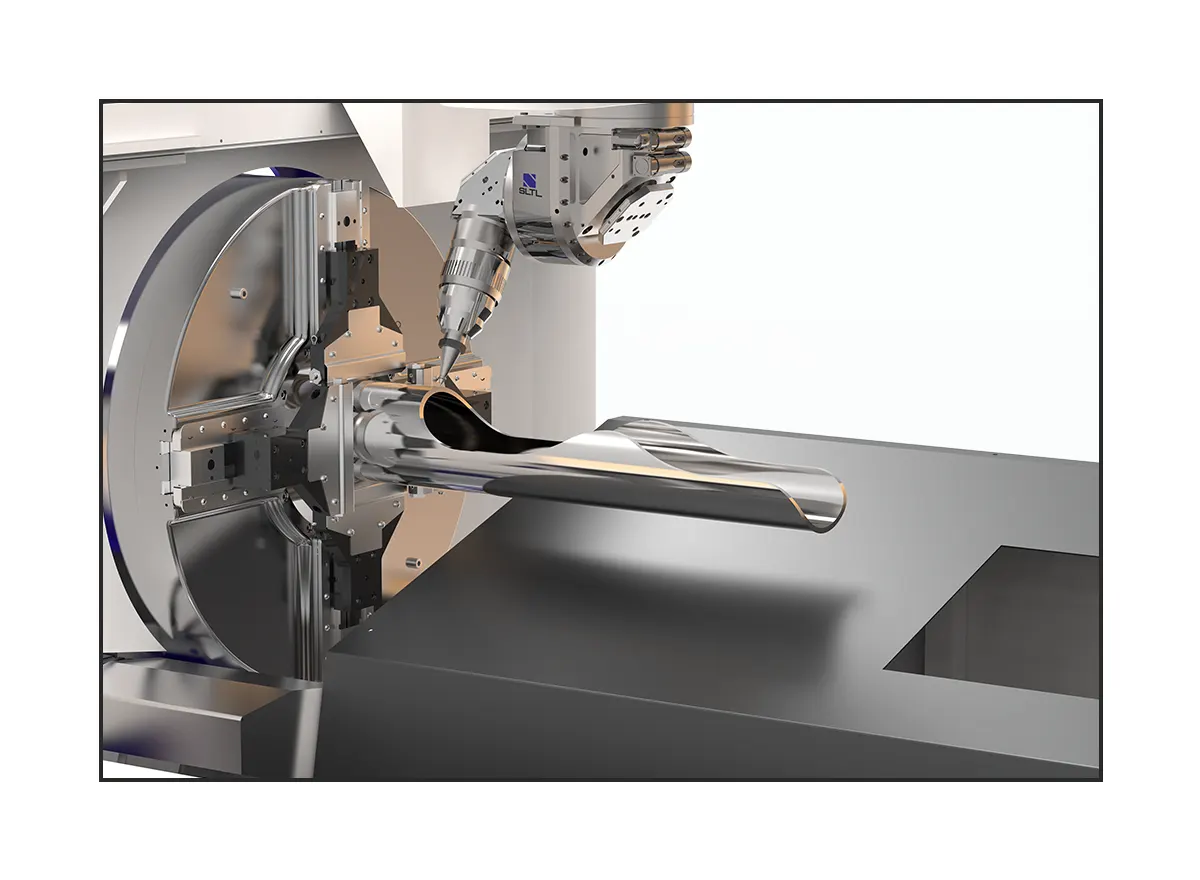

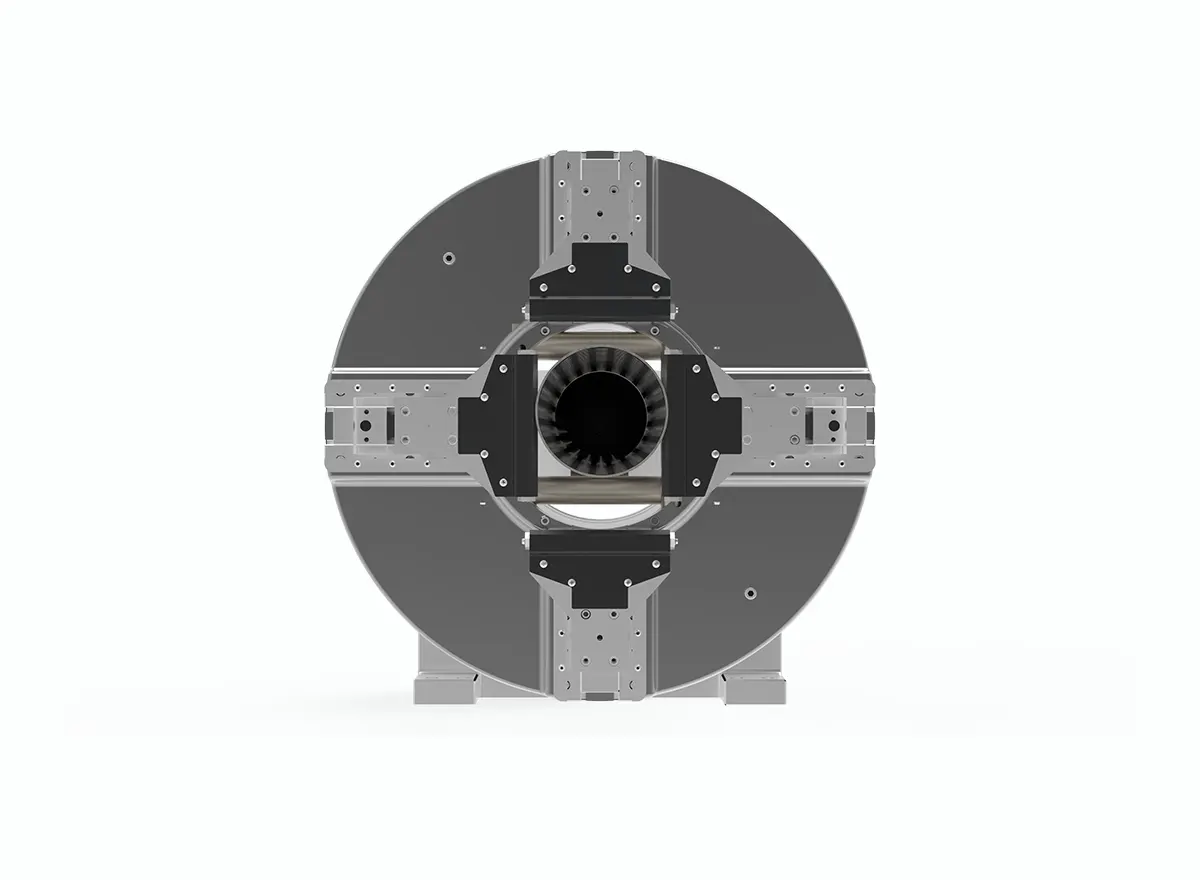

Robust Chuck with Integrated Rotary Axis

The system is equipped with an automatic chuck to provide instant response and fit in different tube geometries perfectly. The chuck system is perfectly calibrated to attain high machining accuracy by avoiding any torsional stress in the tube.

Special Shapes & Profile Processing

Unique integration of the hardware and the software allows the SLTL’s Laser Tube Cutting machines to operate on varied tube shapes like triangles, squares, rectangles, circles, L angel, C channels, I or H beam, pentagon, round oval, ellipse, perfect square, octagon, a rectangle with chamfer, semi-oval and even some angle profiles. With the system’s functional power supply capabilities, it could work smoothly on materials such as SS, MS, Al, Cu, Br, Gi, and more.

Robust Chuck Clamping Mechanism

The system caters to both flexible and adjustable chuck clamping to suit various shapes and contours of tubes with accuracy. The tube cutting series is equipped with a pneumatic chuck to provide instant response and fit in different tube geometries perfectly. The chuck apparatus is perfectly calibrated to attain high machining accuracy by avoiding any torsional stress in the tube. Both the chucks of these laser tube cutting machines are synced with each other which allows calibrated movement and hence provides accurate cutting.

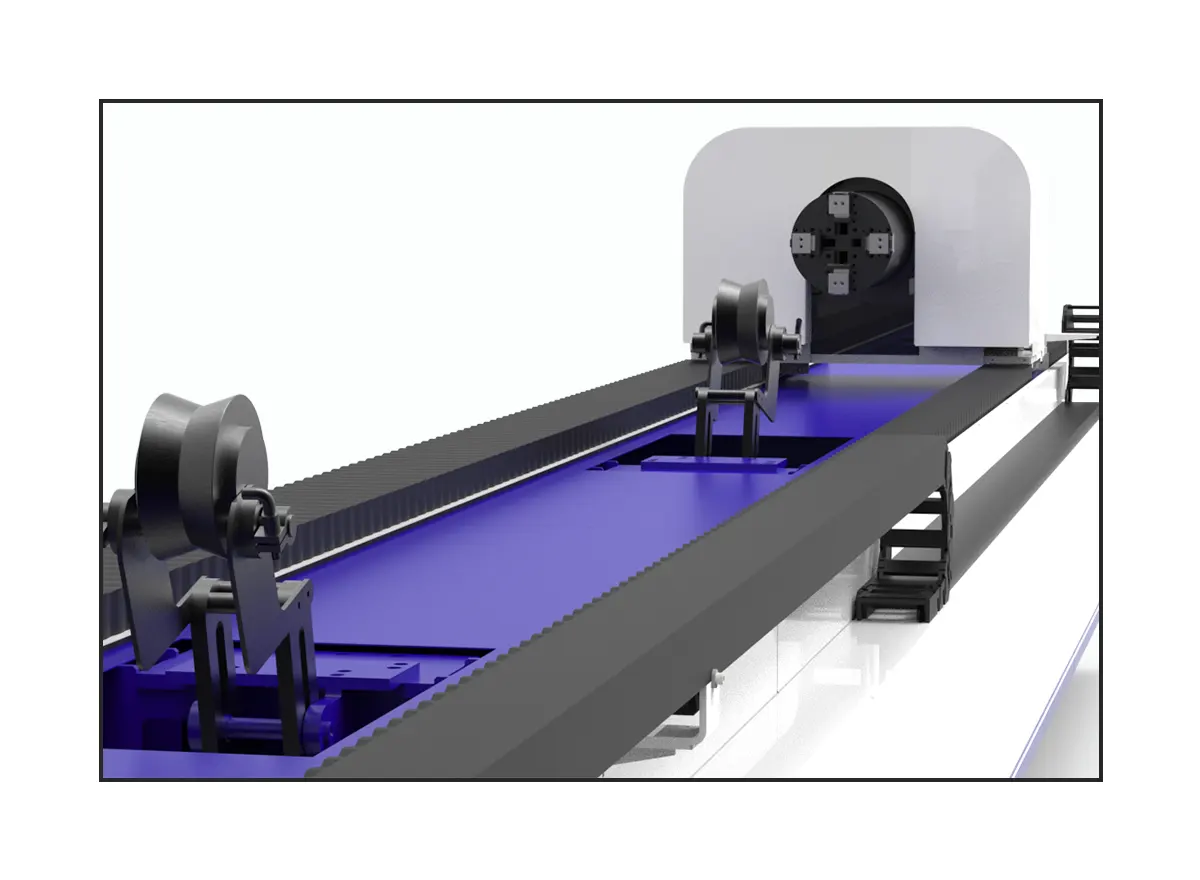

Smart Tube Holding System

SLTL’s Laser tube cutting technology is equipped with an intelligent smart tube holding system to solve the problem of distortion. The laser pipe cutters come with a specifically designed tube holding system with guiding marks to support tubes of all diameters. A pneumatic mechanism-based chuck helps in clamping the tube. The feature is especially effective for cutting long tubes as it allows precise cutting and eliminates the jerks generated during the cutting process remarkably.

Endless Possibilities with Automation

The robust laser tube cutting machines can be equipped with automation like an autoloader/unloader ensuring safe and automatic loading even of special profiles to attain uninterrupted and highest productivity. The power-packed machines can also be integrated with automation for the flexibility of Bevel Cutting application.

Features and Benefits

- this is a list item

- this is a list item

- this is a list item